Importance of Draining Inside Turbine Casing

The main drain line and the bypass drain line are external to the steam turbine. So it is required to seal the portion to prevent leakage of steam and atmospheric.

The Fossil Fuel Power Plants Technology Sciencedirect

As turbine is a rotary mechanical device that extracts energy from a flowing fluid and converts it.

. View week 10docx from ABE 138 at Mindanao State University - General Santos. Another very important requirement in the construction of combustion chambers is providing the means for draining unburned fuel. WORKBOOK 10 PPS Topic Course Outcome Learning Outcome SECTION TIN WORK BOOK FOR POWER.

However malfunctions do occur so TDP-1 offers recommendations for preventing turbine damage that include. A cover or shell that protects or encloses something. Drain includes skirt made on the end of cylindrical housing and caulked in the hole of casing groove to attach the drain to the casing.

Turbine casing drains remove the condensate from the turbine casing during warm-up securing maneuvering and other low flow conditions. 3CL ALMERIA BENEDICT FRANZ F. Answer 1 of 6.

1Casing Drains connected to common flash tank having total 12 no drains connected. The portion from where the rotor exists the turbine casing is called a gland. What maintenance do wind turbines need.

Detection of the presence of water either in the turbine or preferably external to the. There are two cases of particularly which this condition must be filled. The drains should be located on the boiler side of the throttle valve.

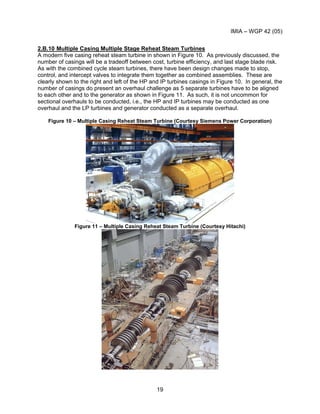

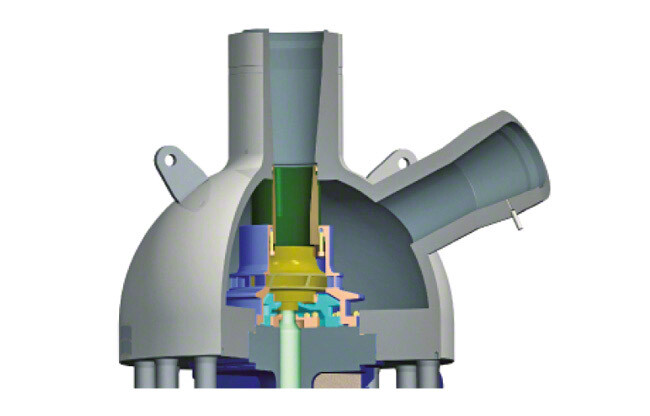

The LP turbine see Figure 6 is located next to the HP turbine. Understanding casing flow in Pelton turbines by numerical. Installed in the steam supply line near the turbine.

The LP turbine is a pressure compounded either single or dual axial flow condensing reaction turbine. Water in any pocket in a turbine casing may cause a slug of water to be carried. Casing may also refer to an enclosing shell tube or surrounding material.

Also in the event of springing a leak excessive compressed air can hinder rapid decompression and. Answer 1 of 2. This drainage prevents gum deposits in the fuel manifold nozzles and combustion chambers.

The drain system further comprises a drain orifice assembly 22 within. Trapped air results in unreliable pressure readings. Wind turbines generally require preventative maintenance checkups two to three times per year.

Casing PKDhakan Abdul Basheer PC Hydel Research and Development Centre Jyoti Limited Vadodara India. Rotor extended outside the casing at both side and rear side. 3Machine stoppages for longer duration.

To design a more efficient steam turbine a casing with proper nozzles and vanes to confine the steam and valves to control the admission of steam to the nozzles should be used. The drain system comprises a main drain line 20 providing a main flow path and a bypass drain line 28 providing a bypass flow path parallel to the main flow path. Drain is meant for removal of liquid accumulated in the groove.

The other subject of the present invention is gas-turbine engine and namely jet turbine engine containing exhaust casing described above. Turbine casing drains remove the condensate from the turbine casing during. - Describes the importance of draining inside turbine casing - Describes with the aids of a sketchcomputer aided drawing function of gland packing steam - Explains the function of manoeuvring valve Explains the role of extraction steam Describes that gland steam pressure is controlled by make up valve and spill valve.

Back flow of steam to the turbine casing from. CASE 1 COLD START TURBINE STARTING IN COLD CONDITION Rotor is big enough in length and is. Low pressure LP turbine.

Inside Turbine leading to corrosion on turbine components. When filling a casing or portion of a casing with water or any other fluid as much air as possible should be removed. ANDRITZ Hydro Rue des Deux-Gares 6.

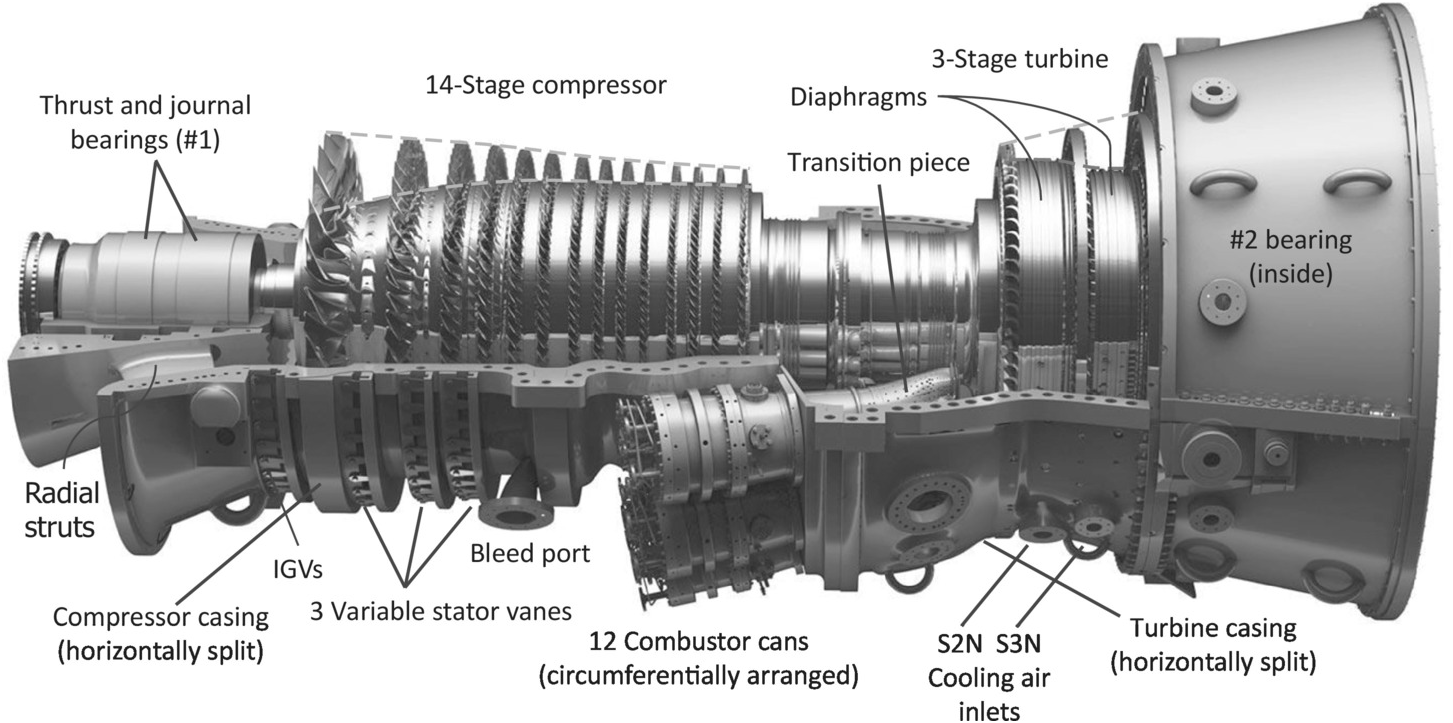

There is chance of steam leakage and atmospheric air ingress to the front and rear gland respectively. Directly to the turbine casing or else they are located inside of a nozzle diaphragm. CASING Although it need not withstand high temperatures like the core of the turbine the materials here need to be strong enough that if a blade were to break off it would be contained inside the casing and not enter the wing or cabin of the aircraft and cause further damage.

In addition it is necessary to drain all portions of the turbine casing where water from condensation may collect. In a turbine rotor rotates inside the casing. US1165922A US87583814A US1914875838A US1165922A US 1165922 A US1165922 A US 1165922A US 87583814 A US87583814 A US 87583814A US 1914875838 A US1914875838 A US 1914875838A US 1165922 A US1165922 A US 1165922A Authority US United States Prior art keywords casing drainage chamber turbines stages Prior art date 1914-12-07 Legal status.

What is the importance of draining inside turbine casing. Steam Drain Trap and bypass valve common drain header 4 from flash tank to. Is of the The turbine casing houses and supports the turbine rotor labyrinth seals and bearings.

The focal point of Grants lesson learned is a 15-MW single-stage turbine supplied by 30000 lbhr of 400-psig saturated steam the type of machine you might find driving a feedwater pump in larger plants. 2LP exhaust end drains. Modern steam turbines have an electronic governor that uses sensors to monitor the speed by examining the rotor teeth.

Machine hence optimized design is required. It has to drain off the water coming out of the buckets without hindering the runner. This facility was using the small turbinegenerator to offset electrical demand while reducing steam pressure for process use.

However it is always true that turbine should be on barring gear. The casing is an essential part of the turbine. What does Casing mean.

A drain system 10 for connection to a steam turbine 14. Safety utmost importance while operating the main engine. Turbine casing drains remove the condensate from the turbine casing during warm-up securing maneuvering and other low flow conditions.

And draining of the fluid and venting of air while filling. A method is described of disassembling an axial flow gas turbine engine having a rotor shaft a rotor blade assembly an outer case a bearing supported from the outer case which is adapted to engage an annular second shaft and to support only the rotor shaft and the annular second shaft and an annular second shaft.

Steam Turbine Archives Mda Turbines

Heavy Steel Casting Total Materia Article

Heavy Steel Casting Total Materia Article

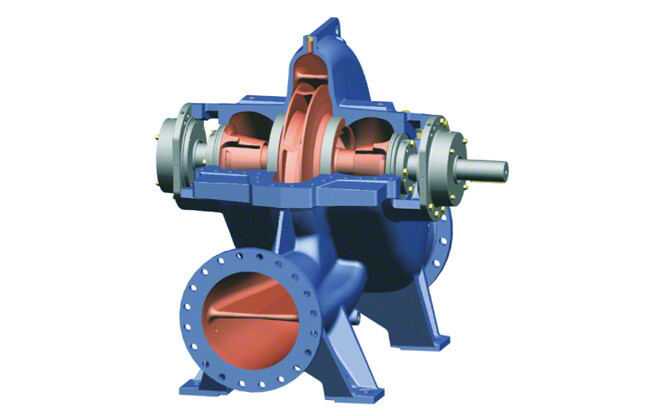

Split Casing Pump Troubleshooting Guide

Side Channel Pump Troubleshooting Guide

Steam Turbine Flow Operation Processing Magazine

The Hardware Chapter 14 Gas Turbines For Electric Power Generation

What Ge Told Stug2020 Attendees About Its Steam Turbines Combined Cycle Journal

Gas Turbine Alignment Mda Turbines

Steam Turbine Flow Operation Processing Magazine

Finding And Fixing Leakage Within Combined Hp Ip Steam Turbines Part Ii

File Under Steam Turbine Operations The Process Technology And Operator Academy

Double Suction Split Casing Pump Real Time Quotes Last Sale Prices Okorder Com

Comments

Post a Comment